Kemlite Piping Solution -Our Industries

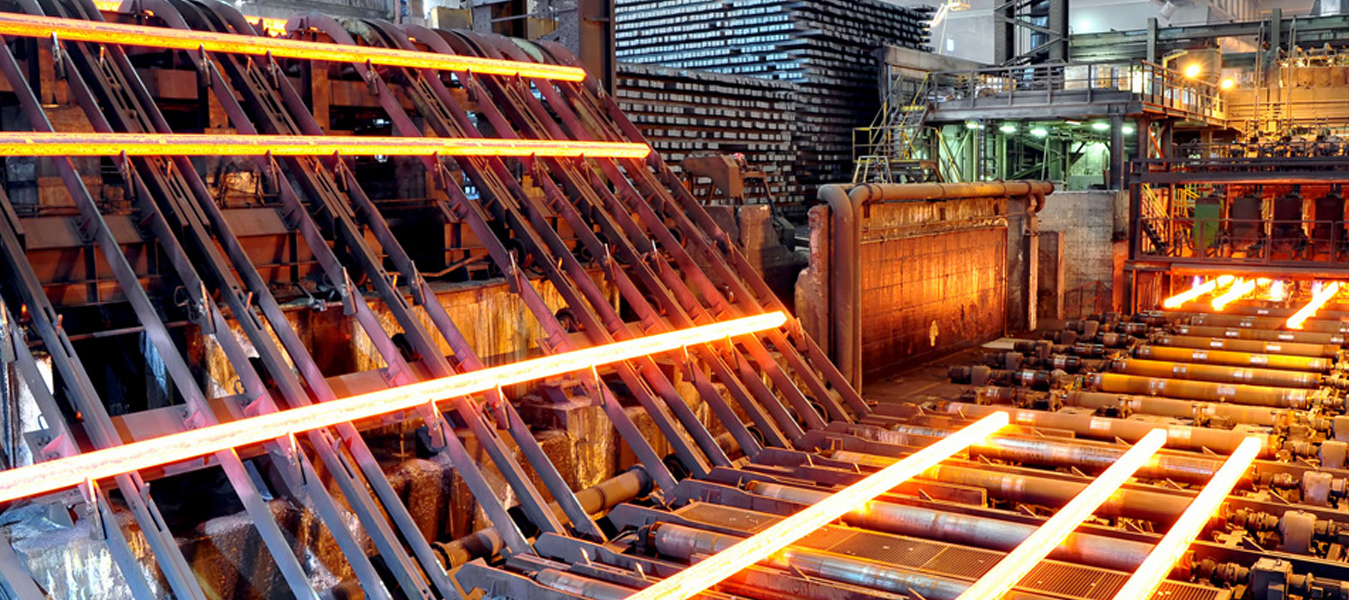

Our Missions are to achieve the targets of our industries and to gain the maximum enhanced growth and expansion with an evolution of best capability and material supply. We are a viable support for our companies in different sector to manage their basic requirement. We support them to achieve the business Objective evenly and profitably.

Our Products

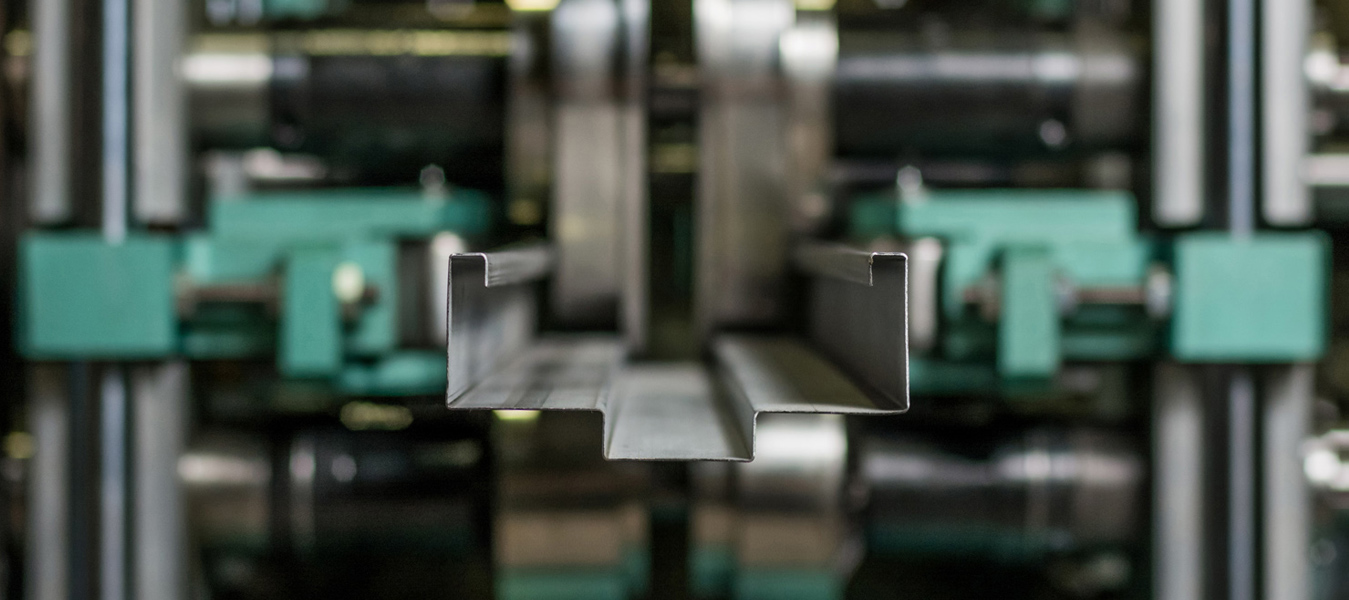

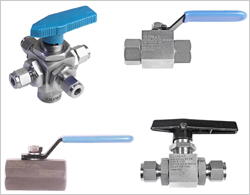

Kemlite Piping Solution is engaged in particular division of products with the best and exceptional quality with exotic range of materials. We have a stockpile of Wide range of sizes and standard dimensional products, where demands can be fulfilled under one roof. We are specialized in manufacturing and stock keeping of Pipes and Fittings (Seamless Pipes, ERW Pipes, Socket-weld Fittings, Butt-weld Fittings, Forged Fittings, Instrumentation Fittings, Ferrule Fittings ) and many other customize requirements are entertained.

Material We Deal

Kemlite Piping Solution always thinks beyond the box where they flaunt their exotic range of grades in material such as Inconel, Monel, Duplex, Super Duplex, Hastelloy, Titanium, Stainless Steel, Copper Alloys, Aluminum Alloys, and High Nickel Alloys Etc. Kemlite is a one stop for every exotic and customize demand for industrial requirements and we feel honored to perform for the same.

Nickel Alloy

Nickel alloys are used extensively because of their corrosion resistance, high temperature strength and their special magnetic and thermal expansion properties.

Monel

Monel is a group of nickel alloys, primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Stronger than pure nickel, Monel alloys are resistant to corrosion by many agents, including rapidly flowing seawater.

Inconel

Inconel is a family of austenitic nickel-chromium-based super alloys. Inconel alloys are oxidation- and corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat.

Hastelloy

Hastelloy and Incoloy are both members of the “super alloy” family, also known as high-performance alloys. As such, they have several key characteristics in common. They both possess excellent mechanical strength, especially at high temperatures, and they are both highly resistant to corrosion and oxidation.

Alloy 20

Alloy 20 is a nickel–chromium–molybdenum alloy developed for applications involving sulfuric acid. Its corrosion resistance also finds other uses in the chemical, food, pharmaceutical, power generation, and plastics industries.

Titanium

Titanium is resistant to corrosion in sea water, aqua regia, and chlorine. The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element.

Duplex Steel

Duplex stainless steel offers excellent resistant to corrosion and very high mechanical strength. The high corrosion resistance of duplex stainless steel ensures significantly more uptime than carbon steels and conventional stainless steels, while the mechanical strength allows for lighter constructions, more compact system design and less welding.

Super Duplex Steel

Super duplex stainless steels are generally more complex, more highly alloyed materials with PREn (Pitting Resistance Equivalent number) = 40.0 and offer even higher strength and corrosion resistance making them suitable for very demanding applications such as offshore marine engineering.

Why Choose Us

Promptness and constant evolutional techniques and products make us worthy to work with. We always focus on our industrial particular demands which always according to their standardized needs.

.jpg)

Third Party Inspection

Our team of experts maintain a vigil on the quality of the products. Every single piece is attached with test certificates and reports. We are continually improving our quality to serve our clients better.

Quick Delivery

We exercise stringent quality control measures for ensuring the accurate dimensions and mechanical properties of our products. we are believing to give the delivery of products within time assign by us and quick delivery as per the customers requirement.

Customer Support

Build strong relationships with our customers – which we achieve, for example, by employing and training local workforces.